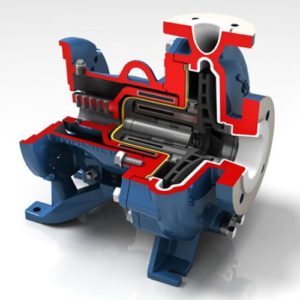

Mag-drive pumps use an outer magnet assembly driven by the pump motor to spin the inner magnet assembly which is connected to the impeller. In between the two magnets is a containment shell which creates a hermetic seal. Having no seal means less of a chance of leaks, which is very important if you are pumping hazardous fluids.

SCG Process stocks FLOWSERVE Innomag pumps for quick delivery. Call us to see if a mag-drive pump will work for your application.

Typical Applications:

- Chemical processing

- Reactor feed

- Chemical waste treatment

- Scrubber systems

- Tank car loading / unloading

- Metal finishing

Innomag Sealless Pumps

“For a cleaner tomorrow”, is where it all starts. Innovative Mag-Drive strives to keep your work environment safe and clean by producing a zero emissions pump. A better tomorrow really does start today.

FLOWSERVE has been manufacturing sealless, non-metallic, magnetically driven pumps since 1998. Their “claim-to-fame” is their Thrust Balanced product line, the TB-mag series. Its introduction revolutionized the non-metallic, mag-drive pumping industry as the first fully thrust-balanced pump with the ability to handle solids. This was truly a first for this class of pumps. No longer do you need perfectly clean liquids! When applied right, an INNOMAG pump can make a real difference for your environment, maintenance staff and operators alike.

Benefits of Innomag Pumps:

- Quality Components. Innomag compounds their own fluroplastics and even does their own rotomolding right in their own factory to ensure quality control.

- Solids Handling. Innomag’s unique design allows you to utilize the benefits of a mag drive pump, even if your process has solids.

Thrust Balanced Impeller Design. Those who deal in day-to-day reliability truly understand the destruction that thrust can cause.