Parts Catalogue

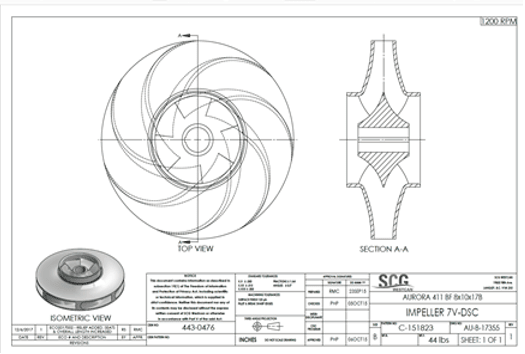

Catalogue Pump Parts:

Casings Bearing frames Bearing frame covers Wear plates | Impellers Shafts Sleeves | Stuffing box covers Packing glands Rotors |

Over 50 popular pump brands in our catalogue, including:

Ahlstrom Pumps Sulzer Pumps Goulds Pumps A-C Pumps | Allis Chalmers Pumps Bingham Pumps Canada Pumps Layne Pumps | Peerless Pumps Ingersoll Rand Pumps Hayward Gordon Pumps HYMAC Pumps |

Foundry Works

Raw Casting

Machining Capabilities

Quality Control

We have a dedicated quality control department that is responsible to ensure that each pump part that leaves our facility is certified to OEM or better specifications. Our specialized equipment, including FARO arms test standard tolerances down to 0.0005-inch to ensure part accuracy. Before a part leaves our facility, it undergoes a detailed quality checklist that includes fits, tolerance, run outs, holes, gauges, threads and surface finish. Once a part passes its quality checks it is inscribed with a code to track maintenance history and to match it to the original drawing. When required, dynamic balancing is conducted in-house to OEM or customer specific specifications.

Pattern Inventory