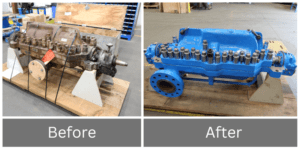

Pump Rebuilds and Overhauls

Our technical staff can provide failure diagnosis, performance troubleshooting and consultations on materials and hydraulic upgrades to help you tackle your toughest applications. With well over 100 years of collective industry experience we are ready to take on all your complex pump rebuild and upgrade challenges.

If you face challenges with discontinued or unsupported pieces of equipment, SCG Process has the resources to re-engineer and replicate your old obsolete parts to OEM or better quality.

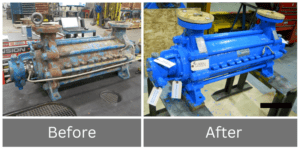

Boiler Feedwater Pump Rebuilds

Every hour of unplanned downtime for a critical pump increases the risk of compromising operational integrity. Boiler feed water pumps are complex and often need to be turned around under tight schedules. We have the expertise and equipment across multiple facilities to rebuild Boiler Feed water pumps to OEM specifications – quicker and at lower cost vs buying new replacement pumps.

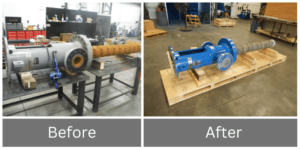

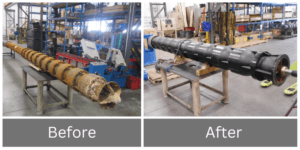

Vertical Turbine Pump (VTP) Rebuilds

Vertical turbine pumps in process and untreated water applications must contend with aggressive media during running conditions. Head loss and increased vibration are indicators that performance has been reduced by operational wear and tear. SCG Process has the expertise and equipment to restore lost capacity with a quality rebuild at our multiple facilities.

Vertical Turbine Pump (VTP) Re-bowling

If your pump has lost performance or has excessive vibration, don’t discard the entire unit. Consider re-rating it to the original specifications while retaining existing components by re-bowling. SCG Process can install a new Flowserve bowl assembly on your VTP that matches the hydraulics and performance of the original across all OEMs.

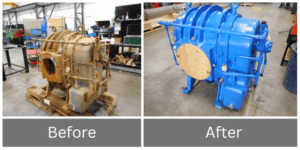

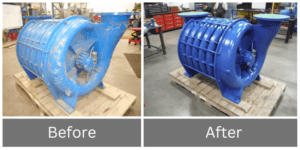

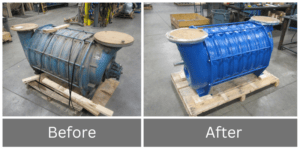

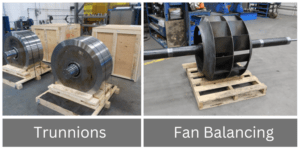

Blower Rebuilds

For many industrial and municipal facilities, the reliable supply of air and vacuum is key to operational integrity. Blowers are critical for safe environmental management and maintaining optimal process conditions. SCG Process has the expertise, equipment, and supply chain to deliver a quality rebuild for your blower or provide a new replacement unit for positive displacement blowers and multistage centrifugal blowers.

Proven rebuilds capabilities for Spencer Turbine, Roots Blowers, Hoffman & Lamson, Gardner Denver, Tuthill Corporation, Copes-Vulcan.

Blower Maintenance

Catastrophic blower failure, such as a seized bearing, leads to costly unexpected downtime and operation disruption. Preventative maintenance addresses problems before they become critical and recovers lost capacity from general wear and tear. We have the knowledge and capabilities across our multiple facilities to keep your equipment running at peak efficiency.

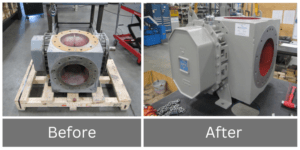

General Equipment Repair

In addition to pumps, we repair a wide range of critical equipment for a variety of industrial facilities. We have the machinery and expertise to restore old worn equipment and parts back to new condition quicker and cheaper then purchasing new.

Types of Large Pumps to Rebuild and Overhaul

SCG Process has manufactured over 90,000 equipment parts to extend pump asset life and we have rebuilt hundreds of large pumps and blowers for industrial and municipal facilities. We specialize in the complex projects where pumps are subjected to harsh conditions and provide services for a wide variety of pumps types including:

• Chemical Process Pumps

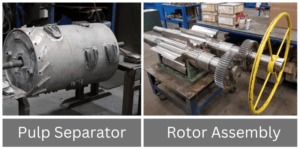

• Pulp Stock and Pulp Process Pumps

• Boiler Feed Water Pumps

• Vertical Turbine Pumps

• Vertical Axial and Mixed Flow Pumps

• Horizontal Split Case Pumps

• Submersible Solids Handling

• Dry Pit Solids Handling

• Vacuum and Process Air Blowers

Our typical pump rebuild and overhaul program scope includes:

• Detailed disassembly, cleaning, and inspection of all components

• Clean, machine and polish impellers, shaft, spigots and other critical components

• Balancing of all impellers and rotating elements

• Repair or replace any wear wings as required

• Repair, replace, and/or upgrade any bearings or seals as required.

• Mechanical seal upgrades where recommended.

• Supply all new hardware, o-rings, gaskets, and bushings

• QA/QC all new components

• Detailed rebuild report complete with phots and tabulations as required

Top 5 Reasons to Rebuild and Service Your Pumps

1. Pump rebuilds are engineered with precision, improving the pump lifespan and reducing the highest expense – unscheduled downtime. With an overhaul of a pump or its components, SCG Process technicians will use 3D scanning, computer guided engineering, the latest welding technology, as well as CNC and CMM machinery to complete your project.

2. Improved Efficiency – Often there are opportunities to improve the efficiency of your equipment during a rebuild. Newly manufactured components using current technology and manufacturing process often afford an increase in total performance. Improved, fit, finish, and tolerance can all contribute to a superior pump rebuild experience.

3. Improved Reliability – Upgrading metallurgy, tolerances, packing, bearing types and coatings has proven to double or even triple pump life. Discussing these options with SCG Process could saves thousands of dollars in life-cycle costs.

4. Product Exchange programs save time, inventory and money. SCG Process supplies a replacement pump, or assembly, while your damaged pump or assembly is being refurbished, you get billed only for the repair work performed on your worn unit.

5. Installing a new equipment can be complicated and expensive. It makes sense to extend the life of your existing equipment for as long as possible as part of an ongoing preventative maintenance and rebuild program within your facility.