Maximize Safety and Efficiency with Polyethylene Chemical Storage Tanks

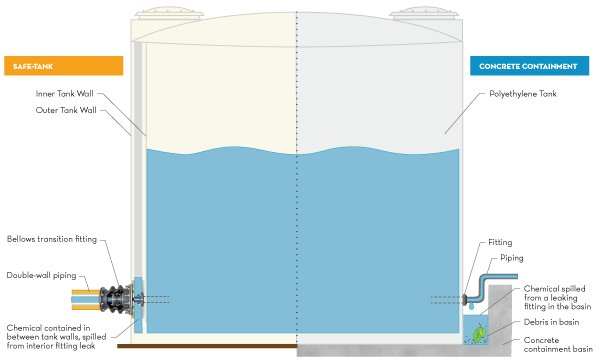

Storing hazardous chemicals requires a system that offers durability, corrosion resistance, and safety while also ensuring easy maintenance and low lifecycle costs. Traditional chemical containment solutions like concrete basins often come with high maintenance costs, limited spill recovery, and environmental risks due to contamination.

SCG Process offers Polyethylene Chemical Storage Tanks from Poly Processing, providing a high-performance, cost-effective alternative to traditional concrete systems. These tanks are designed for superior durability, chemical compatibility, and easy maintenance, ensuring long-term, safe chemical storage.

Advanced Chemical Storage for Safe and Sustainable Operations

Secure, Cost-Effective Solutions for Hazardous Chemical Storage

SCG Process provides advanced Polyethylene Chemical Storage Tanks, offering reliable, safe, and cost-efficient solutions for hazardous chemical storage. With a double-wall design, crosslinked polyethylene material, and SAFE-Tank system, our tanks provide superior chemical containment while reducing your environmental footprint. Whether you need a modular solution or a custom system, we deliver solutions that enhance your sustainability and operational efficiency.

Environmental Responsibility – SAFE-Tank’s secondary containment offers a cleaner, safer solution for chemical storage, preventing spills and environmental hazards.

Customizable Design – Modular construction allows for easy upgrades and system expansions to meet your future needs.

Improved Sustainability – Reduced carbon footprint and lower operational costs with energy-efficient systems.

Long-Term Durability – Built to last with UV-resistant, corrosion-resistant, and chemically compatible materials, ensuring reliable performance.

Reduced Chemical Waste – Efficient discharge systems reduce chemical loss and waste, saving you money on replacement costs.

Compliance and Safety – Meets regulatory standards for chemical storage, ensuring safe, compliant operations.

Key Features:

IMFO® Full Discharge System – Molded flange system for complete tank discharge and reduced maintenance.

Corrosion and UV Resistance – Built to withstand harsh chemicals and extreme environmental conditions.

SAFE-Tank Double Wall Design – Secondary containment to fully enclose the primary tank and prevent chemical spills.

Modular Design – Customizable systems to meet the specific needs of your facility.

Heavy-Duty Construction – Welded steel construction or composite tanks that provide extra strength for large-scale storage.

Easy Installation and Maintenance – Quick assembly, low maintenance, and long-term reliability for ongoing operations.

Innovative & Safe Chemical Storage Solutions

Maximize Safety and Efficiency with Durable Polyethylene Tanks

SCG Process offers a comprehensive range of Polyethylene Chemical Storage Tanks designed to meet the most demanding storage requirements. Whether you need single-wall or double-wall tanks, custom systems, or turnkey solutions, we provide the right fit for your application. Our SAFE-Tank system ensures maximum safety and cost efficiency, eliminating the need for additional containment units while providing reliable storage for hazardous chemicals.

Superior Durability – Corrosion-resistant and UV-resistant materials offer long-lasting protection even in harsh chemical environments.

Safe Storage – The double-wall design provides secondary containment, ensuring safety for both personnel and the environment.

Cost-Effective – Eliminates the need for expensive concrete basins and lowers maintenance costs with easy-to-clean, durable materials.

Full Discharge Capabilities – The molded full discharge system enables complete drainage without manual cleaning, minimizing downtime and maintenance costs.

Chemical Compatibility – Crosslinked polyethylene material ensures safe storage for a wide range of chemicals, with no compatibility issues.

Enhanced Environmental Protection – SAFE-Tank’s secondary containment prevents spills and leaks, offering easy inspection and safe chemical recovery.

Resources

Key Applications:

- Municipal Water Treatment

- Oil & Gas

- Wastewater Treatment

- Pulp and Paper

- Pharmaceutical

- Food and Beverage

- Agriculture

- Chemical Processing

Comprehensive Expertise

Support for complex fluid transfer, treatment, and transport systems.

The SCG Advantage

Full Lifecycle Support

From installation and commissioning to rebuilds, repairs, and reverse engineering.

Tailored Pump Packages

Engineered, integrated, and factory-tested to your specifications.

Get the Right Equipment for Your Application

From pumps and valves to flow measurement and chemical feed systems, choosing the right product is critical for reliability and performance. Tell us what you’re working on and our technical experts will pinpoint the best solution based on your application, conditions, and operating goals.

Put Your Project in

Expert Hands

Find a Specialist Near You

Connect with a local SCG Process expert who understands your challenges and is ready to provide a tailored solution.