Smart. Secure. Streamlined.

The HogWash Septage Receiving Station by SCG Process.

Septage treatment presents growing challenges for municipalities and plant operators—inconsistent waste loads, manual handling, poor data visibility, and limited control all put critical assets at risk. With hauled waste reaching concentrations up to 80 times stronger than municipal influent, unmanaged dumping can lead to treatment upsets, regulatory noncompliance, and asset damage.

Developed and manufactured by SCG Process, the HogWash Septage Receiving Station delivers an automated, secure, and data-driven approach to receiving, treating, and monitoring hauled waste. Designed for both plant operators and haulers, HogWash provides a fully integrated solution that enhances control, improves safety, and modernizes facility operations.

Intelligent, Automated Septage Receiving

Bringing automation, traceability, and control to every stage of waste reception.

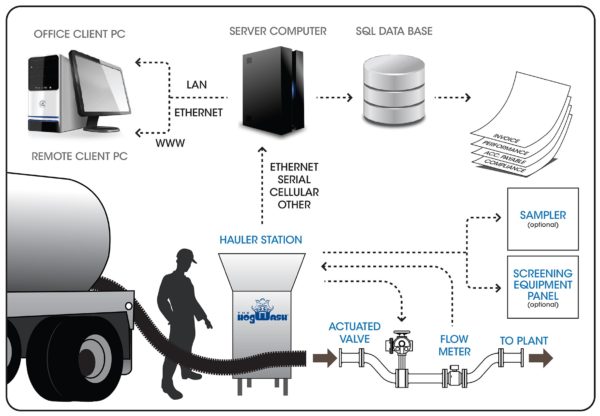

The HogWash system combines advanced automation, smart access control, and real-time monitoring into one cohesive unit. With key-card or fob access for approved haulers and seamless communication with plant systems, it ensures controlled waste reception, traceable transactions, and simplified billing.

Every HogWash station is custom engineered to meet site-specific requirements—including data collection, communication, and treatment integration—ensuring compliance and operational efficiency.

Integration with existing SCADA and billing systems

Automated waste receiving, tracking, and reporting

Secure access control for approved haulers

Real-time data logging and remote monitoring

Custom design to meet municipal and regulatory needs

Key Features:

Automated Hauler Activation – Key card or fob system ensures controlled access for approved haulers.

Real-Time Data Logging – Tracks all transactions locally and remotely for full transparency.

Smart Flow Control – Stainless steel discharge connection with actuated valve and electromagnetic flow meter for accurate measurement.

Integrated Treatment Monitoring – Optional pre-treatment and instrumentation for effluent quality control.

Custom Configurations – Engineered to match your plant’s communication, data, and regulatory requirements.

Smarter Septage Management for Operators and Haulers

Real-time control, accountability, and automation—streamlined for both plant operators and haulers.

The HogWash Septage Receiving Station is more than just a discharge point—it’s a fully integrated information and control system that simplifies operations, enhances security, and improves efficiency across your entire facility. Designed with both plant operators and haulers in mind, HogWash creates a seamless flow of data, transactions, and compliance management—all in real time.

Enhanced Asset Protection – Safeguard headworks and downstream equipment from overloads and unregulated waste.

Automated Recordkeeping – Simplify environmental reporting with built-in data logging and traceability.

Secure Access Control – Authorize haulers with key-card or fob access and enable automated lockouts when required.

24/7 Operational Access – Approved haulers can unload at any time—no staff supervision required.

Accurate Billing Integration – Automatically record and process transactions for streamlined invoicing.

Faster Turnaround – Minimize delays with quick system authorization and automated load tracking.

Business Insight – Give haulers and operators visibility into daily load activity and performance metrics.

Operational Efficiency – Reduce manual intervention and optimize staffing through automation.

Resources

Key Applications:

- Municipal and Regional Wastewater Treatment Plants

- Industrial Waste Receiving and Pretreatment Systems

- Landfill Leachate and Septage Processing Facilities

- Portable Sanitation Waste Management

- Remote or Unstaffed Septage Receiving Stations

Comprehensive Expertise

Support for complex fluid transfer, treatment, and transport systems.

The SCG Advantage

Full Lifecycle Support

From installation and commissioning to rebuilds, repairs, and reverse engineering.

Tailored Pump Packages

Engineered, integrated, and factory-tested to your specifications.

Get the Right Equipment for Your Application

From pumps and valves to flow measurement and chemical feed systems, choosing the right product is critical for reliability and performance. Tell us what you’re working on and our technical experts will pinpoint the best solution based on your application, conditions, and operating goals.

Put Your Project in

Expert Hands

Find a Specialist Near You

Connect with a local SCG Process expert who understands your challenges and is ready to provide a tailored solution.