Maximize Efficiency with FLOWSERVE SIHI Liquid Ring Vacuum & Compressor Pumps

Industrial processes that depend on reliable vacuum or air compression often face equipment failures, cavitation, and corrosion—especially when exposed to aggressive chemicals, vapors, and fluctuating pressure conditions. Traditional pumps struggle to maintain stable operation and efficiency in these demanding environments.

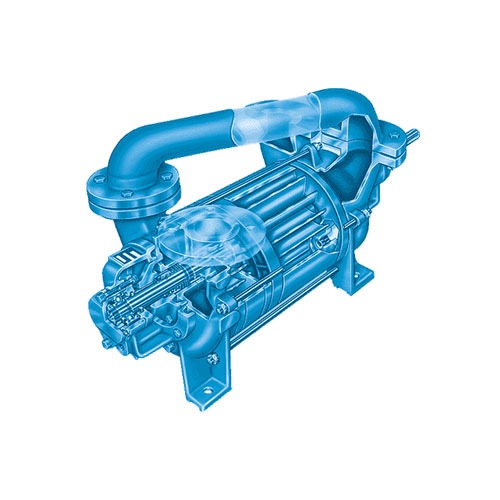

SCG Process delivers FLOWSERVE SIHI liquid ring vacuum and compressor pumps, engineered for durability, performance, and safety. Built with robust materials and proven liquid ring technology, these systems provide continuous, trouble-free operation for both vacuum and compression applications across multiple industries.

Why Choose SCG Process for Vacuum and Compression Systems?

Performance: Proven FLOWSERVE SIHI engineering delivers consistent efficiency under challenging vacuum and compression demands.

Durability: Constructed for harsh chemical and vapor environments with minimal wear and downtime.

Safety: Liquid ring design provides intrinsic protection when compressing volatile or mixed gases.

Support: Backed by SCG Process’ expertise, including system design, integration, and field service throughout Western Canada.

FLOWSERVE SIHI Product Line Overview

LPH Series:

Reliable, high-performance liquid ring vacuum pumps with one moving part for minimal maintenance. Available in single-stage (low to medium vacuum) and two-stage (medium to high vacuum) designs, with customizable construction materials and seal liquids for application flexibility.

LEM Series:

Compact, close-coupled vacuum pump series built in North America. Features cavitation protection, single mechanical seal, continuous solids purge, and ultimate vacuum approaching 29″ Hg (25 Torr)—ideal for space-limited, multi-service operations.

KPH/KEH Series:

Advanced liquid ring compressors capable of both vacuum and positive discharge pressure. Designed for safe gas compression, these pumps ensure stability and reliability when handling complex vapor or gas mixtures.

Resources

Key Features:

Single or Two-Stage Configurations – Designed for low to high vacuum performance across diverse process conditions.

Minimal Maintenance Design – Only one moving part (impeller/shaft assembly) and no metal-to-metal contact for long service life.

High Reliability and Uptime – Proven FLOWSERVE SIHI engineering ensures consistent performance and low wear.

Robust Construction Materials – Available in multiple alloys and coatings to handle aggressive chemicals and vapors.

Flexible Liquid Sealing Options – Operates with various seal liquids for enhanced process compatibility.

Safe Gas Compression – Liquid ring principle prevents friction-based ignition, ideal for handling volatile gas mixtures.

Key Applications:

- Degassing and Drying Systems

- Gas Compression and Recovery

- Filtration and Evaporation Processes

- Steam and Autoclave Systems

- Vacuum Tables and Process Chambers

- Vapour Handling in Chemical or Refining Operations

Comprehensive Expertise

Support for complex fluid transfer, treatment, and transport systems.

The SCG Advantage

Full Lifecycle Support

From installation and commissioning to rebuilds, repairs, and reverse engineering.

Tailored Pump Packages

Engineered, integrated, and factory-tested to your specifications.

Get the Right Equipment for Your Application

From pumps and valves to flow measurement and chemical feed systems, choosing the right product is critical for reliability and performance. Tell us what you’re working on and our technical experts will pinpoint the best solution based on your application, conditions, and operating goals.

Put Your Project in

Expert Hands

Find a Specialist Near You

Connect with a local SCG Process expert who understands your challenges and is ready to provide a tailored solution.