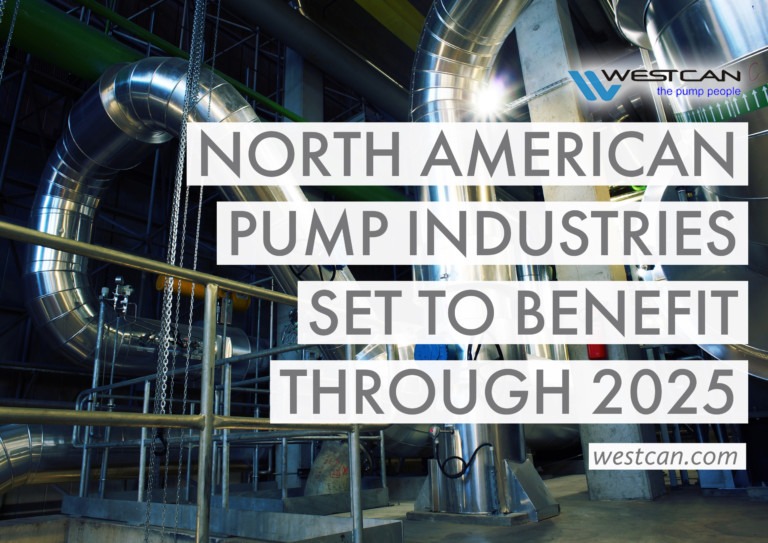

pump industry forecastIn a report released in December 2016 by Grand View Research, a US-based market research and consulting company, the global market for industrial pumps is forecast to undergo significant growth. From USD 50 billion in 2015, the market value is predicted to reach USD 88 billion by 2025.

The Benefits of Backup Pumps in Potash Processing

Millions upon millions of people around the world depend on faultless processing of potash in order to maintain a steady supply of potassium for fertilizers. Potash production continues to be one of Canada’s most valuable industries. Companies in Saskatchewan account for around 1/3rd of global potash production and generate $1.6 billion in gross revenue each year. … Read more